LIFETIME ACCESS. Trainings never expire.

$58.00 USD (One Time Payment)

$58.00 USD (One Time Payment)

1 Day Welder Bundle:

☑️ Watch on any device (phone, computer, tablet)

☑️ Includes Buying Guides + Cheatsheets

☑️ Start anytime - trainings never expire!

☑️ Upon payment, logins for the 1 Day Welder Program will be sent directly to your email.

30 Day Money-Back Guarantee

If you are not completely SATISFIED with the entire 1 Day Welder Program, then contact me within 30 Days for a full refund, no questions asked!

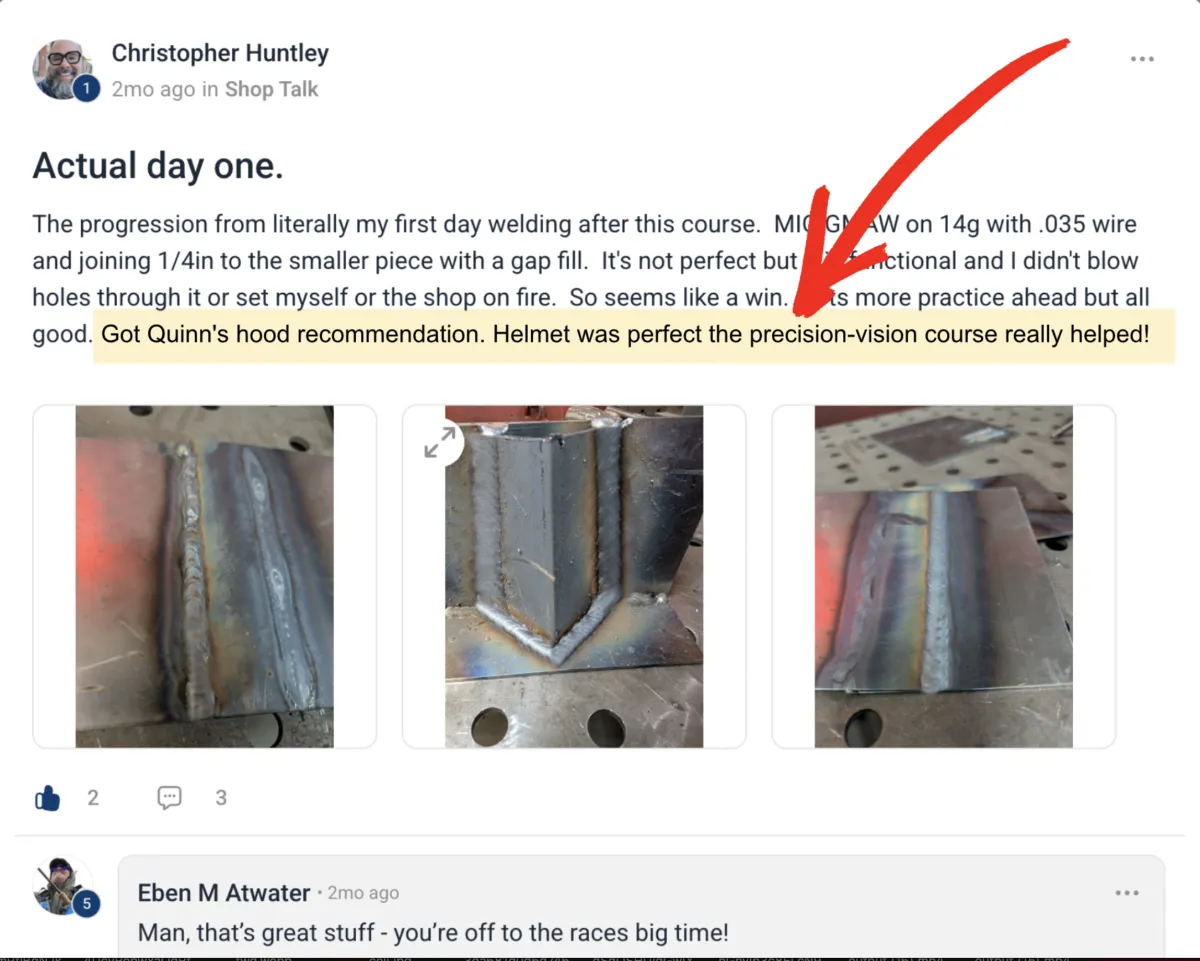

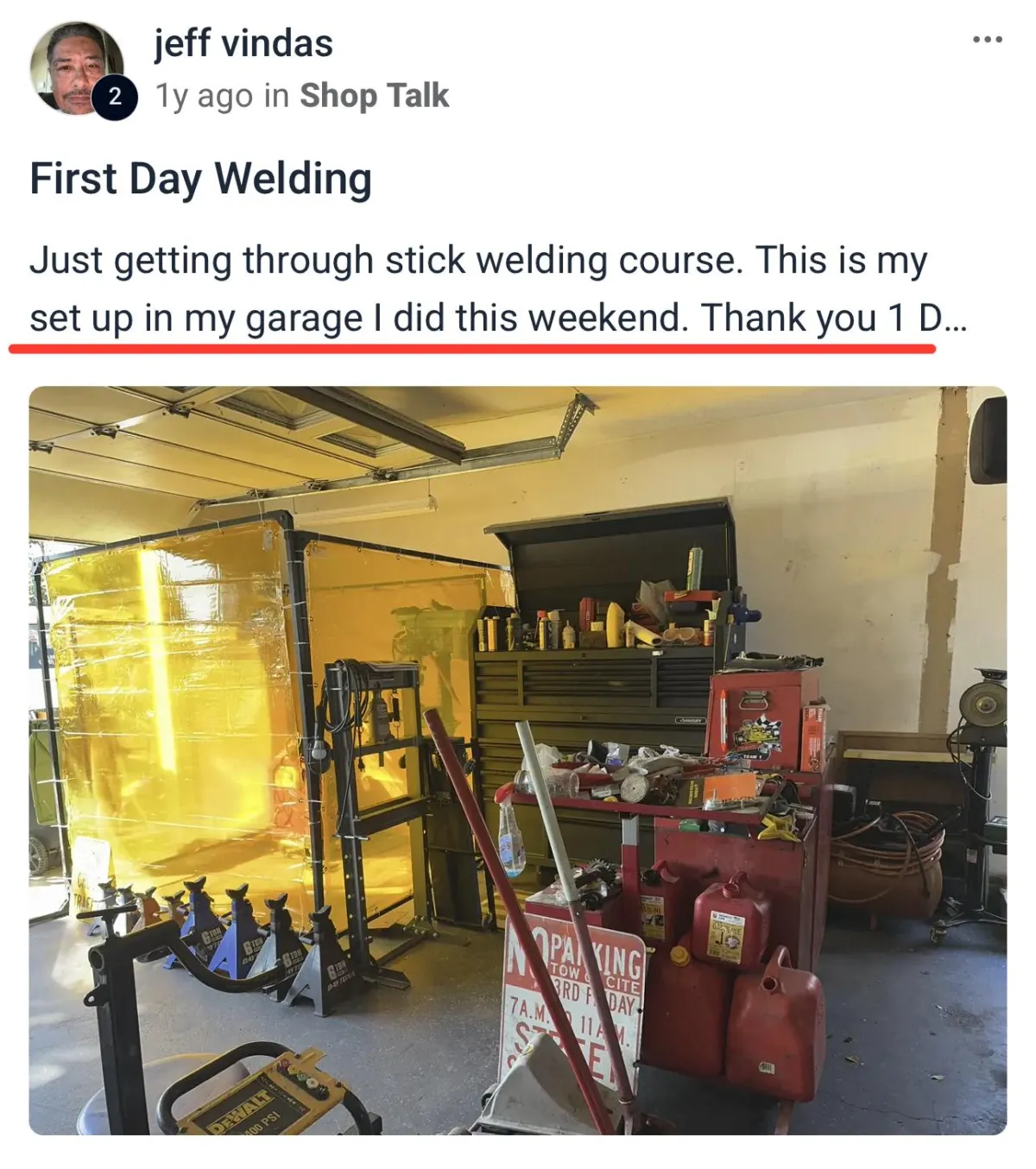

26,000+ Happy Members!

⭐️⭐️⭐️⭐️⭐️

What students are saying 👇🏼

"I've been wanting to learn welding for 20+ years but didn't know where to start. Thank you for finally creating this course.”

- Leroy W.

You're about to get access to:

50+ videos of pure-value training for Metal Fabrication, TIG, MIG, and Stick Welding!

Huge discounts on quality welding equipment from Eastwood, PrimeWeld, and YesWelder

The ultimate Recommended Welder Buying Guide (Updated This Year)

6 Bonus Cheatsheets

Easily watch on any device

Lifetime Access at a MASSIVE Discount

New welding content added by request

Questions answered on the daily and much more!

5 for 1 Bundle ENDS SOON

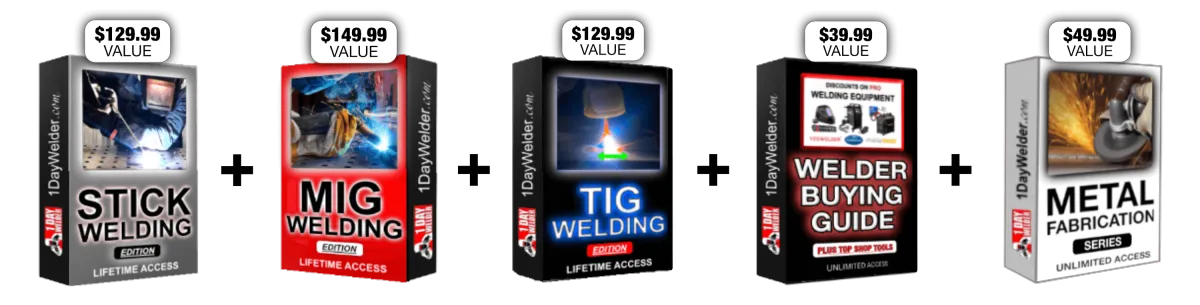

Course #1: Fundamentals & Buying a Welder (Value $39.99)

✅ Polarity Settings Cheatsheet: Fix the #1 rookie mistake with machine setup! Includes a step-by-step video how to set-up your machine polarity.

✅ Processes Pro's & Con's Cheatsheet: Compare Stick, MIG, and TIG with an easy guide that helps you decide what’s best for you. Includes a step-by-step video walking though all the pro's and con's.

✅ Welder Buying Guide + Student Discounts: Get my personal list of top-rated welders (with killer discount codes) ranging from $100 to $4,500. I’ll also teach you how to score a great secondhand welder for under $100 — and how to test it before you buy.

✅ How Welding Actually Works: A clear and simple explanation of what happens when you strike an arc.

✅ Metals 101: Carbon Steel, Stainless Steel, Bronze, and Aluminum

✅ Polarity & Current: Alternating, Straight, and Reverse (AC, DC, DCEN, DCEP)

✅ Flux-Cored vs Solid Wire: Breaking down SMAW, GMAW, FCAW, & GTAW

✅ Shielding Gases: When to weld with Argon, CO2, Helium, or Mixed Gas

✅ Choosing Your Process: Stick, MIG, or TIG: We go over which welder is best for you based on the projects you want to complete. I'll run you through every possible welding job you can think of - so you aren't guessing what you need.

Course #2: Metal Fabrication & Safety (Value $49.99)

✅ Safety Gear: How to protect yourself against sparks, arc flashes, and welding burn. Access to a bonus list of recommended gear.

✅ 3 Essential Fabrication Tools: Exactly what you need to cut, grind, and smooth metal. For under $100, these 3 tools will complete 95% of all projects.

✅ SETUP Shop: How to layout a safe welding area in your garage. driveway, or yard. You will feel confident getting started FAST in your own welding space.

✅ Buying Metal: A step-by-step guide on how to get metal at better prices from local suppliers.

✅ Prep Metal for Welding: How to properly cut, grind, and smooth metal to get it ready for welding!

Course #3: Stick Welding (Value $129.99)

✅ Stick Amperage Settings Cheatsheet: How to dial in your settings based on metal thickness. Use this cheatsheet for quick reference in your garage or shop. Imperial & Metric Units!

✅ Electrodes: How to choose the right rod for the job, including 6010, 6011, 6013, and 7018.

✅ Amperage: Dial in your settings for strong welds and a smooth arc start. Includes a printable cheatsheet for fast reference.

✅ Striking the Arc: Easy techniques to avoid your rod sticking and frustrating restarts.

✅ Technique #1: Arc Length: The key to a smooth arc and deeper penetration.

✅ Technique #2: Rod Angle: Understand how to properly manipulate the weld puddle.

✅ Technique #3: Travel Speed: How to gauge the perfect pace for more consistent beads.

✅ Practice Exercise: Butt Joint: Strengthen your skills with this step-by-step exercise welding the most common joint.

✅ Practice Exercise: Lap Joint: Applying the fundamental techniques to build confidence welding overlapping metals.

✅ Practice Exercise: Tee Joint: Get clean T-joints on both thick and thin material for stronger project builds.

✅ Practice Exercise: Corner Joint: Sharpen your precision welding corners — critical for metal fabrication work.

✅ Troubleshoot: The most common mistakes and how to troubleshoot stick welding issues.

✅ TIPS - Welding "Out of Position": How to tackle vertical and overhead joints.

✅ Structural Repair: Behind the scenes how to brace and weld heavy equipment repairs (real-world repair skills that pay off)

Course #4: MIG Welding (Value $129.99)

✅ Wirefeed & Voltage Settings Cheatsheet: Settings for both flux-core and solid-wire MIG welding. Quickly reference the right numbers while you work. Imperial & Metric Units!

✅ GMAW & FCAW: Assessing your welder and switching polarities.

✅ Machine Set-Up: Wire-types, drive-roll tension, shielding gases, checking for leaks, and the importance of contact tip diameter.

✅ Wire Feed Speed & Voltage: Get your machine “purring” as we walk through adjusting your settings based on metal thickness.

✅ Technique #1: Stick Out: How to gauge the distance to your workpiece and control your arc for solid penetration.

✅ Technique #2: Gun Angle: Pushing vs Pulling & how to place your hands for the correct work angles.

✅ Technique #3: Movement: Find your rhythm and travel with a steady drag or a smooth weave for consistent welds every time.

✅ Practice Exercises: Butt Joint, Lap Joint, Tee Joint, Corner Joint: Hands-on tutorials tackling the most common fabrication joints — you’ll practice each one and build long-lasting muscle memory.

✅ Thin Sheet Metal: Three techniques to avoid burn-through and warping — excellent for auto body work and light gauge material.

✅ MIG Welding Aluminum: Understanding spool guns, metal prep, and technique adjustments so you can confidently weld aluminum with your MIG machine.

Course #5: TIG Welding (Value $149.99)

✅ TIG Amperage Settings Cheatsheet: Easy-to-follow AC/DC TIG amperage per material, metal thickness, and machine setup. Nail your settings to save time and material. Imperial & Metric Units!

✅ Overview: TIG Welding Terminology: Get familiar with the fundamentals without getting intimidated or overwhelmed.

✅ TIG Torch Setup: Air-cooled vs Water-cooled Bodies, Cups, Collets, Gas Lenses, Stubby Kit Upgrades, Furick Cups, Pyrex Lenses, & more...

✅ Sharpening Your Tungsten: The best all-purpose electrode+diameter, plus the right way to prep for smoother arc starts and better control.

✅ Machine Setup: Ideal shielding gas pressures per cup size, plus an in-depth machine setup to dial in your settings - no guesswork required.

✅ Filler Wires + Metal Prep: Which filler alloys to use for different metals and the most simple way to clean material.

✅ ARC Start: Mastering lift-arc, scratch-start, and high-frequency.

✅ Technique #1: ARC Length: Discover how maintaining the right distance improves penetration and weld quality.

✅ Technique #2: Torch Angle: Avoid common mistakes by learning how to hold your torch for better bead control.

✅ Technique #3: Feeding the Filler Metal: Build muscle memory for feeding wire smoothly while keeping your torch steady.

✅ Technique #4: Travel Speed: Learn how to find your rhythm and avoid cold starts or overheated metal.

✅ Practice Exercises: Butt Joint, Lap Joint, Tee Joint, Corner Joint: We tackle every joint style step-by-step so you’re fully prepared to weld real-world fabrication projects.

✅ Silicon Bronze: A special technique reduce warping and even weld dissimilar metals.

✅ Aluminum Deep Dive: AC Settings, Torch Setup, Alloys & Filler Metals

✅ Aluminum Techniques + Troubleshooting: Assessing your aluminum welds plus tips for improving common aluminum welding mistakes.